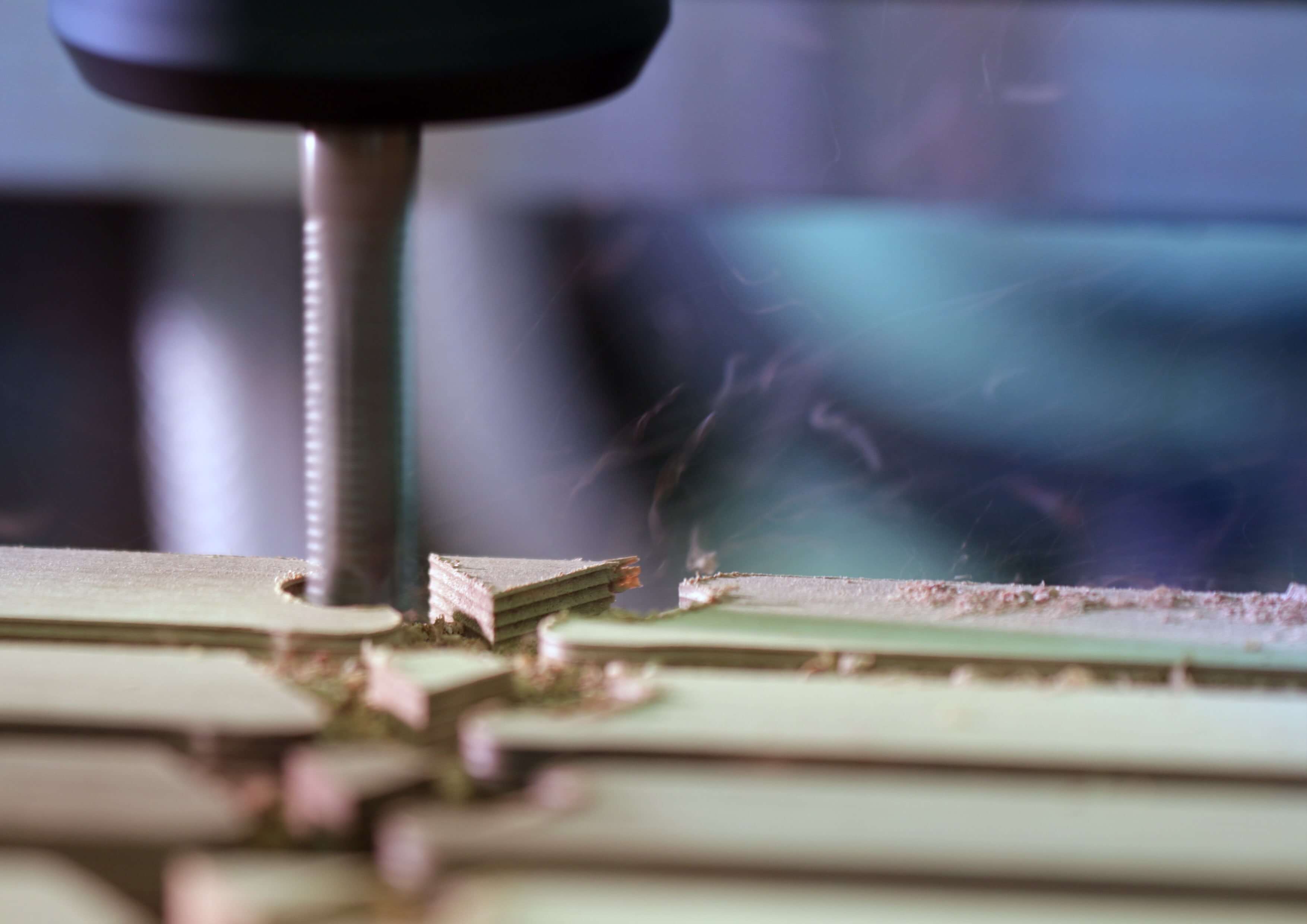

Panel press.

Panel press. The Art of Gluing.

Gluing is an art. Our many years’ experience allows us to glue the slats, so the joint is almost invisible. To this end, we check each slat for defects before the press. We also check the colour, structure, and growth ring position. We attach particular importance to the combination of individual wood slats so that the finished panel has a uniform look and is professionally glued.

Gluing individual wooden slats into panel or sheet parts has been one of our strengths for years.

Semiautomatic panel press

With our semiautomatic panel press (also called a bonder), panels up to three metres long can be glued efficiently. For longer panels, we have an additional manual press where we can produce panel lengths of up to 7m.

In full agreement with our environmental principles, our glues are formaldehyde-free, odourless, and particularly suited to Minergie ECO buildings.

Panel gluing line for the production of solid wood panels

Our semi-automatic panel gluing line can produce solid wood panels in formats up to 3050 × 1130mm. The operator assembles the boards on the set-up table, in the desired design and width. The automatic infeed pulls the individual slats past the glue roller and conveys the slats in front of the gluing starwheel. Then the individual slats are joined and clamped together in the press. The boards leave the press ready for further processing after at least 30 minutes of compression. Further processing usually involves sanding the board before it is further processed and surface-treated according to the customer’s wishes.