Laser.

Laser Technology.

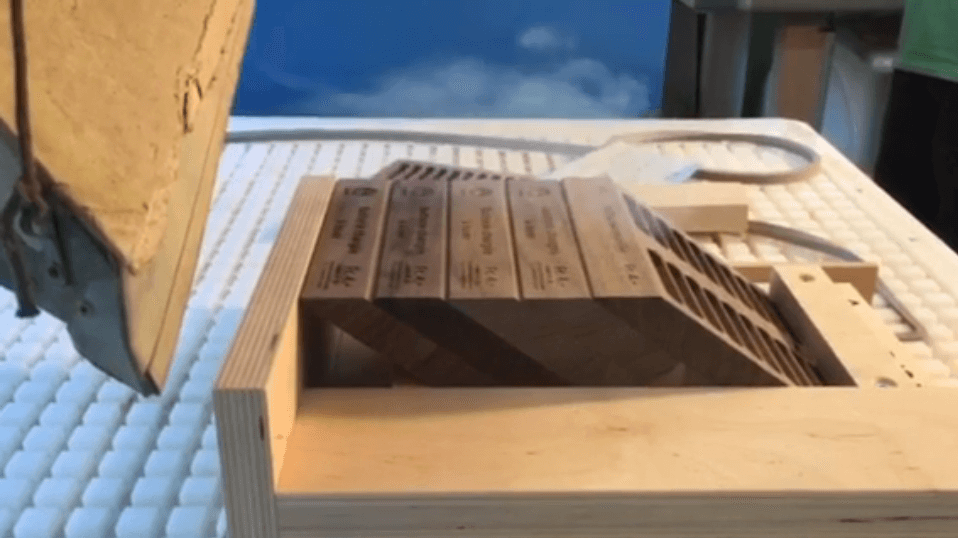

We are one of the few companies in Switzerland that also use laser technology. Our specialists use their years of expertise to customise the workpiece. It takes a lot of knowledge and experience to programme the machine to enable complex engravings. With our laser, we can engrave surfaces of different sizes. Engravings, letterings, company logos, pictures, symbols or even perforations can be realised.

Laser as a complement to milling

Engraving wood surfaces with a laser or even cutting wood materials requires a lot of experience and intuition. The range of available machines is large and handling them is extremely complex. A laser beam cuts many materials, including various types of wood. Not every type of wood – indeed not even every single piece of wood of the same type – can be lasered in the same way. Each material requires its own characteristics of the laser beam. Among other things, the wavelength, pulse frequency and pulse energy density of the light beam are decisive for the quality of the cut.

Lasertechnology

Like any technology, lasers have specific peculiarities that need to be known and considered at the design stage. The most important ones are:

- A laser beam is approximately 0.2 mm thick, which minimises cutting loss.

- Thanks to the thin beam, sharp corners can be cut. Pocket milling is only possible to a limited extent and is time-consuming.

- The heat generated during the cutting process causes the cut surfaces to oxidise, they “crust”.

- The cut edges do not splinter out and only need to be reworked for applications that require a radius.

- Wood materials that have glued or phenolic resin surfaces should not be processed with laser. Waterproof glued chipboard is also not suitable for laser processing.

- Laser is particularly suitable for thin materials.

- The non-contact cutting eliminates the need for clamping devices.

- The cut surface is not 100% rectangular, especially with thick boards.

- Because wood is a natural material, density, resin, and moisture as well as other specific properties have a major impact.

Giotto 3-axis CO2 laser

Thanks to the performance and high flexibility of our 3-axis laser system, various processings are possible.

Use the advantages and let us advise you on your individual requirements and wishes. The 3-axis laser can be used to laser a wide variety of patterns, brandings, perforations or simply texts.

TECHNICAL INFORMATION

- Machining space without shifting the workpiece 600 x 600 mm

Power 135 watts

For the parts to be processed we use various file formats, e.g., photo formats such as JPEG, TIFF or vector files such as PDF, DXF, EPS, etc.) It depends on the design to be lasered which file format is required.