Electrical energy and heat.

From renewable, ecological raw materials.

TECHNOLOGY FOR A CLEANER ENVIRONMENT

Since December 2018, we are proud operator of our own combined heat and power unit (CHP). A modular system for generating electrical energy and heat from renewable, ecological raw materials.

Environmental facts

Energy efficiency homemade

- Since December 2018 we have been operating a combined heat and power unit (CHP) with an output of 260 kW thermal and 165 kW electric. Standardised and ecologically produced wood pellets are used as fuel.

- Principle: Wood pellet gasification and combustion of the gas via a motor that drives a generator and thus produces electricity.

- The thermal energy is injected into the existing heating network as “waste heat”. The electrical energy can be injected into the power grid of the power station.

- About 850 tons of wood pellets are supplied annually via the 100m3 pellet silo. The water tank of the same size ensures smooth operation between the CHP unit and the heating network.

NATURAL POWER 4

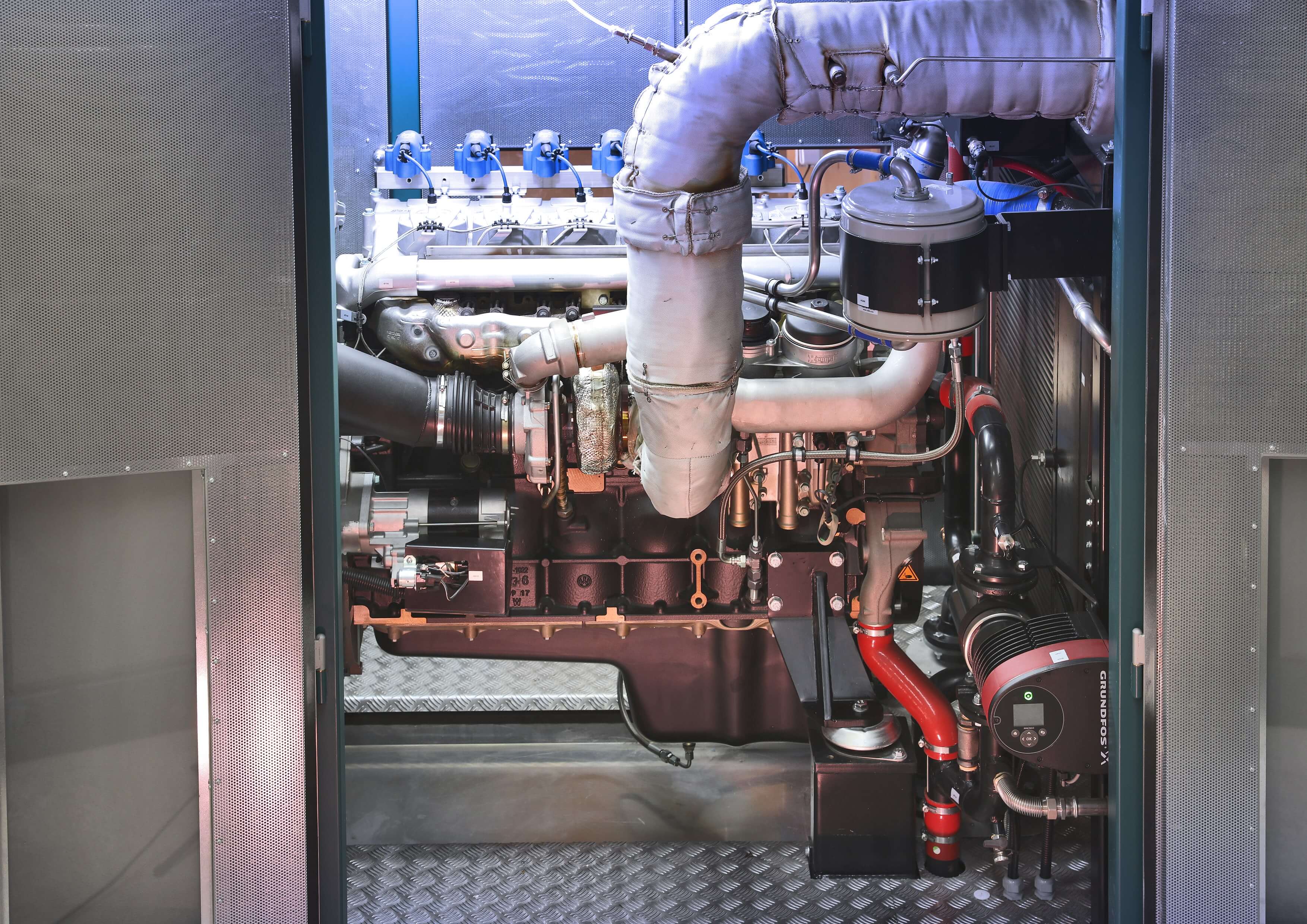

Burkhardt wood gasifier V 3.9 + BHKW ECO 165 HG

- Gasification of wood pellets

- Pellet consumption: 110 kg/h

- Cooling of the gas via gas heat exchanger

- Extraction of heat energy of approx. 60 kW

- waste materials are ash and coke

NATURAL POWER 5

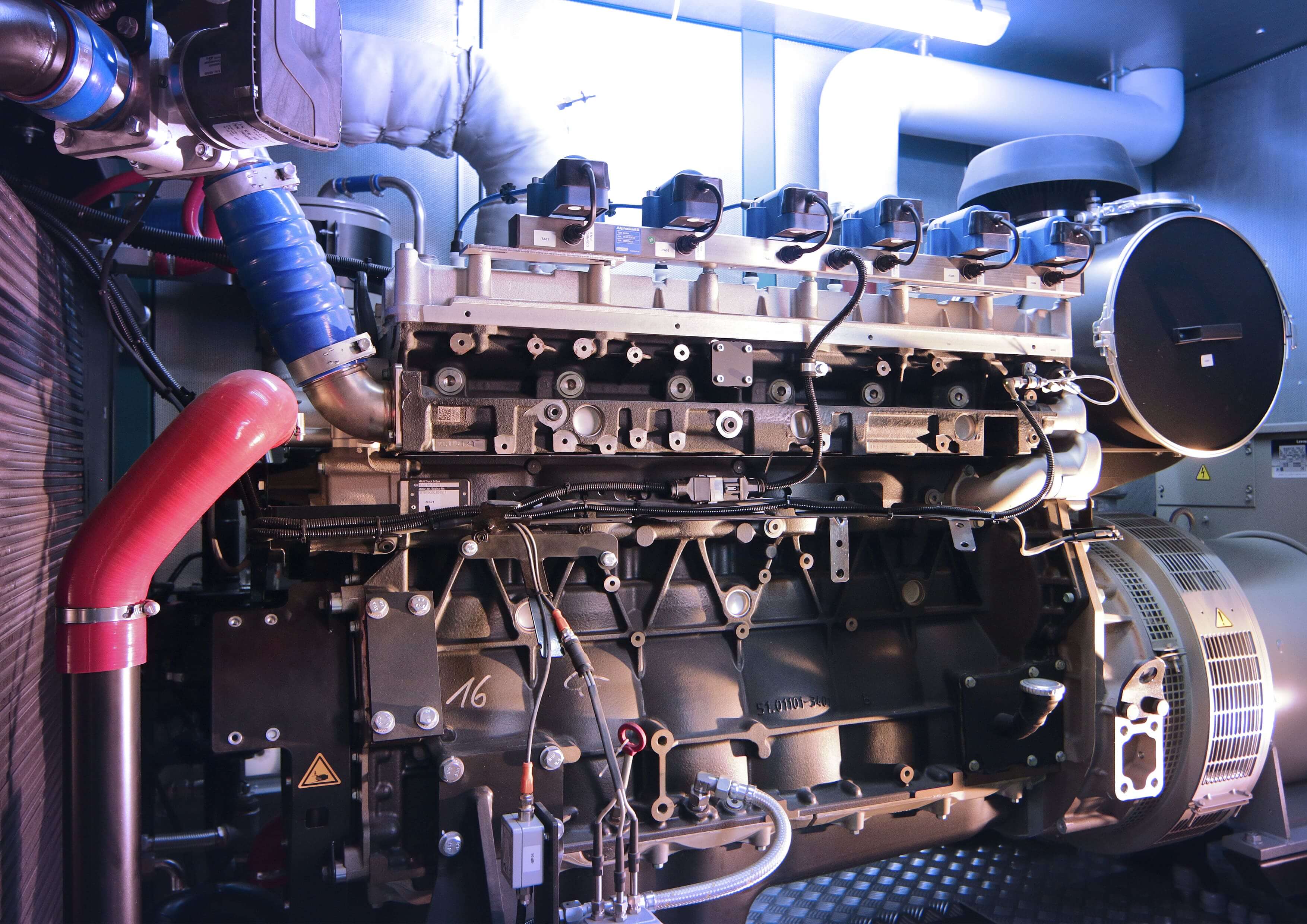

Ottomotor, converted MAN engine without ignition oil

- Combustion of the gas from the pellet gasifier

- Converted 6 cylinder MAN truck engine

- Generator drive with wood gas

- Extraction of heat energy of approx. 210 kW

- Extraction of electrical energy of approx. 165 kW

- Electric efficiency approx. 30%

- overall efficiency approx. 77%