CNC.

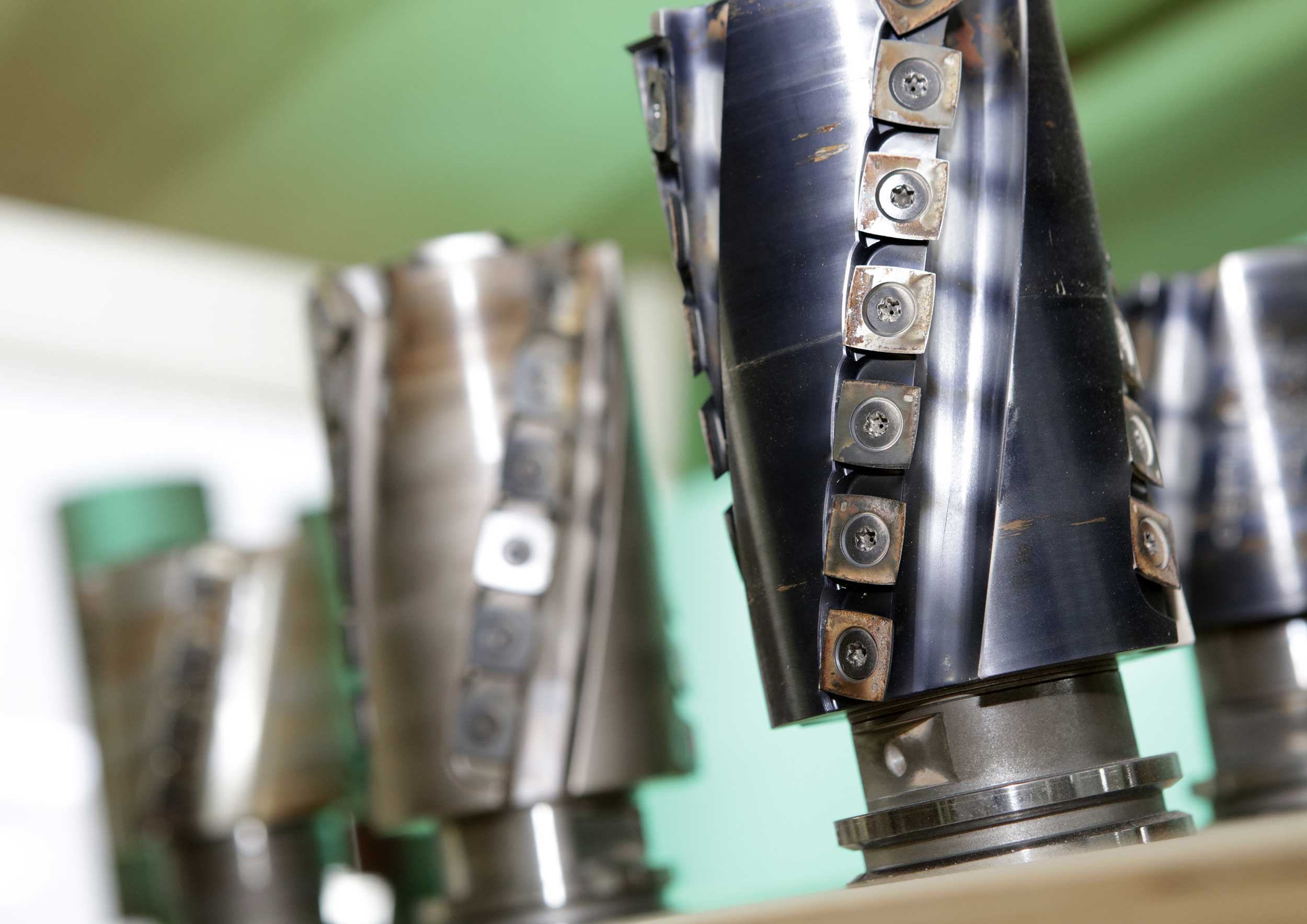

State-of-the-art technology. CNC milling.

We use state-of-the-art CNC milling machines to produce individual components of all kinds in solid wood and wood-based materials. Using the latest CAD/CAM software, we process your specifications and implement your plans – from prototype to series production.

CNC Milling

CNC milling is the most widely used subtractive manufacturing technology. CNC milling uses various cutting tools to remove material from a solid block to produce a part based on a CAD model. Wood as well as metals or plastics can be processed with CNC milling. We are the specialists in solid wood processing.

CNC milling offers many advantages in manufacturing:

Precision

- CNC milling offers excellent accuracy and repeatability and can produce parts with very tight tolerances, making it ideal for high-end applications.

- CNC milling is suitable for single jobs as well as to produce small, medium up to large series due to its high repeatability.

Profitability / Competition

Another advantage is the possibility of complete machining operations. A workpiece is clamped once and all the necessary operations such as milling, drilling, sanding can be carried out in just one run. This in turn increases the accuracy of the workpieces. It also means that a workpiece can be finished in a short time.

Safety at work and health care

- The CNC takes on operations that are strenuous and sometimes risky for humans. As a result, the ergonomic strain on employees is reduced and work safety is increased

State-of-the-art machinery

Our machine park includes four five-axle and one four-axle CNC machines. The four-axle machine provides processing in three axes (x, y and z) in the Cartesian coordinate system. The fourth axle forms the drill head of the four-axle machine. It rotates 360° on the horizontal axis. Our five-axle machines can additionally move their milling units three-dimensionally along the a and c axes.

During demanding 5-axis processing, several axes are moved simultaneously, e.g., turning, swivelling and moving. These simultaneous coordinated and calculated movements are called interpolation. This also allows us to mill three-dimensional shapes out of solid wood, such as a sphere.

Maka CR 27 1 Tamdem – Technical specifications

Short & concise

- Year 2009

- CNC machining centre with 5-axis technology CR 27

- For high-speed machining of wood materials, aluminium, plastics and composites.

- This machine is equipped with two independently usable milling units. It is virtually two machines in one that can process different parts at the same time. Both units have tool changers with 32 places for quick tool change.

Machining sizes

- 2 times 1500 x 1500 x 420mm

- Or tables coupled, 1 x 3000 x 1500 x 420mm

Areas of application

The machining centre CR 27 in stand portal design is based on a proven design concept that ensures high driving dynamics and thus first-class milling results. This series meets the high demands of multi-sided and free-form machining and guarantees massive chip removal with optimum machining quality.

The CR 27 1 5-axis high-performance milling centre has been designed for precision work and versatile machining operations and finds its use in the manufacture of products such as knife handle shells, instrument parts, rifle stocks, furniture components, loudspeaker casings, etc.

Maka CR 27 2 Tamdem – Technical specifications

Short & concise

- Year 2001

- CNC machining centre with 5-axis technology CR 27

- For high-speed machining of wood materials, aluminium, plastics and composites.

- This machine is equipped with a milling unit and a drilling unit. While a part is being milled on one table, it can be drilled on the other table in tandem operation. The drilling unit has 7 vertical and 12 horizontal drilling spindles, which allows efficient drilling work. The machine has a tool changer with 16 places for quick tool change.

Machining sizes

- 2 times 1500 x 1250 x 420mm

- Or tables coupled 3000 x 1250 x 420mm

Areas of application

The machining centre CR 27 in stand portal design is based on a proven design concept that ensures high driving dynamics and thus first-class milling results. This series meets the high demands of multi-sided and free-form machining and guarantees massive chip removal with optimum machining quality.

The CR 27 2 5-axis high-performance milling centre has been designed for precision work and versatile machining operations and is used in the manufacture of products with multiple drilling holes, mainly furniture components such as bed studs (bed legs) or other frame parts.

Maka CR 27 3 Tamdem – Technical Specification

Short & concise

- Year 2004

- CNC machining centre with 5-axis technology CR 27

- For high-speed machining of wood materials, aluminium, plastics and composites

- This machine is equipped with two independently usable milling units. It is virtually two machines in one that can process different parts at the same time.

- Both units have tool changers with 32 places for quick tool change.

Machining sizes

- 2 times 1500 x 1500 x 420mm

- Or tables coupled, 1 x 3000 x 1500 x 420mm

Areas of application

The machining centre CR 27 in stand portal design is based on a proven design concept that ensures high driving dynamics and thus first-class milling results. This series meets the high demands of multi-sided and free-form machining and guarantees massive chip removal with optimum machining quality

The CR 27 3 5-axis high-performance milling centre has been designed for precision work and versatile machining operations and finds its use in the manufacture of products such as knife handle shells, instrument parts, rifle stocks, furniture components, loudspeaker casings, etc.

Maka PM 270 – Technical Specifications

Short & concise

- Year 2013

- CNC machining centre with 5-axis technology PM 270

- For HSC processing of wood, wood-based materials, plastics and composites.

- This machine is equipped with a milling unit and has a tool changer with 51 places for quick tool change.

Machining sizes

- 7600 x 1600 x 420mm

Areas of application

The 5-axis universal machining centre PM 270

in gantry design is used for the processing of wood and wood materials in individual production or small batches, for example, for interior fitters, shopfitters, design furniture manufacturers and staircase manufacturers.

The dynamic moving gantry machine is designed for heavy machining operations and demonstrates economic efficiency through process reliability, long service life and minimum auxiliary times for loading.

The milling centre is used for the production of products such as large tabletops, bar covers, long components to be processed, but also smaller parts for beds or other furniture are manufactured on it.

Biesse Rover C 6.5 – Technical Specification

Short & concise

- Year 2007

- Rover C is the new machining centre for the uncomplicated production of furniture, stairs and components of windows and doors of any shape, size and thickness. Specially designed for heavy processing that requires the use of large tools and aggregates.

- This machine is equipped with a milling unit and has a turret tool changer with 8 places directly at the unit and another external changer with 22 places to be able to change tools quickly.

Machining size

- 4850 x 1535 x 250mm

Areas of application

The high stability of the structure allows the processing of parts with X / Y / Z dimensions up to 4850 x 1535 x 250 mm, with the highest precision and surface quality.

The technology of the Rover C enables the processing of workpieces with complex shapes, guaranteeing quality, precision and lasting reliability. The milling centre finds its application in the production of products 3 or 4 axes processed parts such as flat parts, simple table tops, other more simple furniture components.

Maka MK 7 S – Technical Specification

Short & concise

- Year 2018

- The compact 5-axis CNC machining centre MK 7 is the worldwide proven all-rounder in the machine programme from MAKA. The stand portal machine offers ideal prerequisites for the high-precision processing of small and medium-sized workpieces.

- This machine is equipped with a milling unit and has a tool changer with 20 places for quick tool change.

Machining size

- 2200 x 1000 x 600mm

Areas of application

The compact, rigid design of the MK 7 ensures a high dynamic load capacity. Even at high feed rates, outstanding machining precision is guaranteed. The milling centre is used for the manufacture of smaller products that require 5-axis processing. This machine is used almost exclusively for the production of knife handle shells.