AMZ Racing.

With passion to the top.

AMZ RACING – WITH PASSION TO THE TOP!

The Akademische Motorsportverein Zürich (AMZ) is an ETH Zurich project. Future engineers work with great commitment on the constant further development of electronic motor technology. We are proud to be a partner in this project. Our team's motto is also "Nothing is impossible". Thanks to the latest technology, innovative spirit and passion. This links our company to the ETH project.

Every year, young engineering students at ETH Zurich build a new electric race car. The team and car take part in races all over Europe as part of Formula Students. Formula Students is the largest university engineering competition in the world. The ETH Zurich team in number 1 in the world among Electric Teams. We are thus particularly happy to be AMZ’s partner.

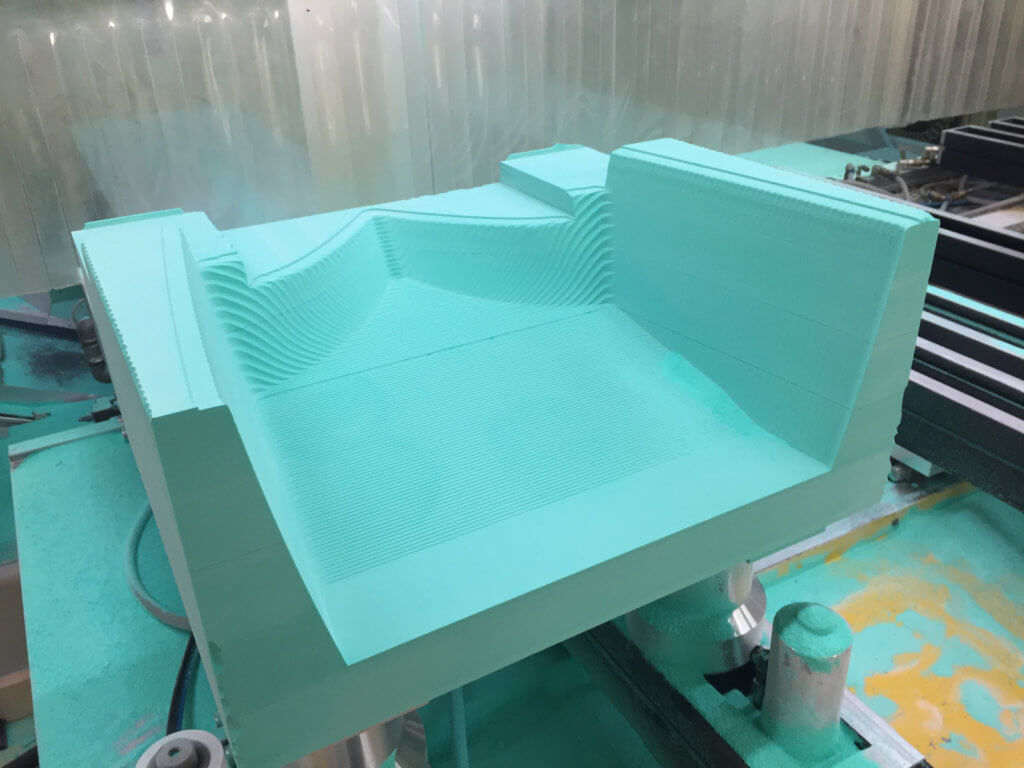

Precisely milled negative form

Our task for the project was to develop a negative form out of what is called tooling epoxy for the steering casing and then to mill it, with absolute precision. The steering casing is mounted in the forward part of the underbody. For this reason, the shape has a lot of influence on airflows in the underbody area. Thanks to our many years’ knowledge of five-axle milling techniques along with CNC technology, we were happy to take on this challenge.

AMZ team’s instructions were clear and neatly structured and already drawn out in 3D. Based on the positive of the steering casing, our team built the negative in a material that was new to us and which we were not used to handling. The particular challenge was the precise milling of the three-dimensional horizontal and vertical surfaces. The radii are very small and far underneath the part. The 3D surfaces were also important, and their surfaces had to be milled neatly and without large traces or post-processing.

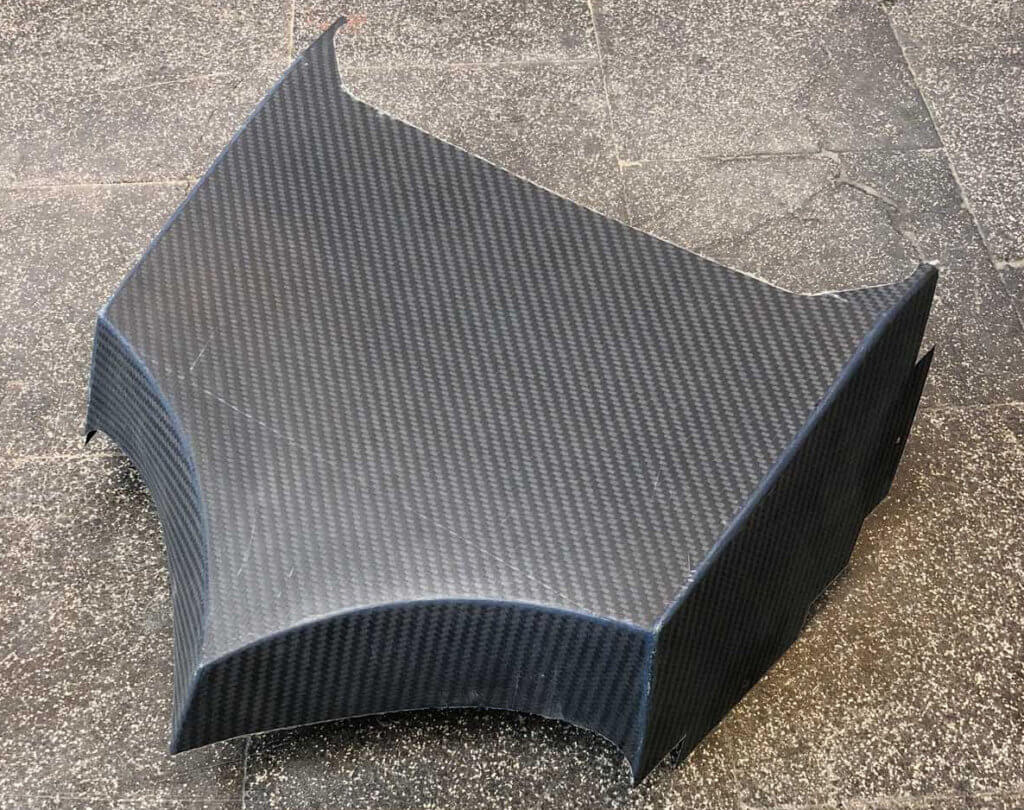

Manufacturing of the steering casing

Before continuing with the processing, the negative form was polished and sealed manually. Then the cut-off positions made of carbon fibre were cut, laid in the negative form and well pressed. In a next step, a vacuum sack was pulled over the form in order to apply even pressure to all the layers. Finally, everything was placed in a special oven and the material hardened. Now the positive of the steering casing can be removed from the form and mounted on the racing car.

Transmitting knowledge

The ETH team was looking for a partner who could bring knowledge of milling technology and the necessary technological infrastructure. Their request pleased us greatly because we like to share our knowledge. Besides technical colleges and universities, we advise architects, carpenters and designers. We have already been able to realise a few project from technical colleges and universities. We like to take on new challenges and to find solutions together. Both sides benefit: We receive new impulsions and can simultaneously transmit our knowledge.

Would you like some advice? We look forward to your call.

More information on the project at WWW.AMZRAZING.CH

Best regards

Thomas von Rickenbach

Owner and CEO